ENGINEERING

We will check

if the construction is safe

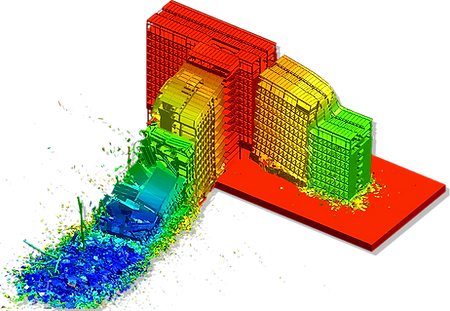

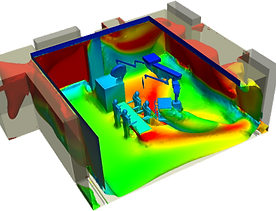

There are multiple factors to take into account when deciding how a commercial building should be ventilated, such as the building’s position, wind exposure, entrance locations, and more. This is where CFD simulations can help, enabling you to validate the use of natural convection in a building and reduce the costs of artificial air exchange systems.

Wind Engineering

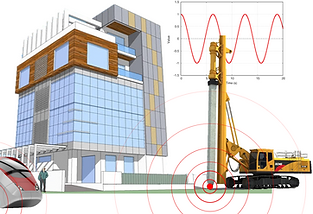

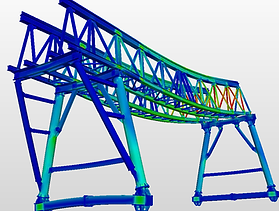

Vibrations

Fire Smoke Analysis

We can test different factors—wind loads on buildings and vortex shedding effect on the immediate vicinity. From real-world wind tunnel experiments to virtual computational fluid dynamics (CFD) evaluation, any amendment to an existing area or newly planned urbanization can be investigated quite intricately in the design phase.

HVAC / Thermal Comfort

Simulation and HVAC duct design software can give three-dimensional insights into the whole flow field, while taking into account all physical effects and the full geometry of the duct. By performing a CFD analysis of the airflow through the duct, we intended to study the effect of varying the number of guide vanes as well as find methods to eliminate or at least mitigate recirculation regions

Knowing the response of the structure to a stimulus is essential for closely analyzing strains and stresses over time. Dedicated operators handle the various process: harmonic linear mechanics (periodical stresses), transient dynamics on a reduced modal basis or physical basis (linear or non-linear, along with numerous integration schemes), spectral analysis and combination of seismic loads or random linear dynamics (interspectral densities)

Material Strength

These behaviors are available for numerous modelings and finite elements since the De Borst algorithm makes it possible to apply them easily to shells and multi-fibre beams. Nonlinearities resulting from large displacements may be modeled in various ways. Non-linear operators use global criteria of convergence and criteria based on physics reference values (stresses, distortions, etc.)

We can simulate smoke, temperatures, velocities, toxicity, and other outputs of the FDS analysis. We use parallel processing to speed the solution, conform your meshes to the geometry to reduce the number of cells and solution time, and change the resolution of different meshes to focus on regions of interest. We can reduce the time required to build complex models for the fire dynamic simulation.

Fatigue Analysis

Most failures of industrial components in normal operation are due to fatigue. Its latent nature is only equaled by its noxiousness, which is why the evaluation of this type of phenomenon is important from the design stage. Depending on the type of fatigue (low cycle fatigue, high cycle fatigue, etc.) the type of stresses (deterministic, random, periodic, multiaxial, distortions, etc.), component or stress tensor.